Upcoming Event: Project Haystack Connect 2015

Innovative, Open Source BAS Network Technologies

Contemporary Controls attended the community-focused Project Haystack Connect 2015 Conference which brought together systems integrators, technology providers and end users.

Contemporary Controls attended the community-focused Project Haystack Connect 2015 Conference which brought together systems integrators, technology providers and end users.

The Haystack standard addresses one of the key challenges facing the industry today-the ability for device data to be easily shared among different applications. Smart devices that monitor and control our modern-day world produce vast quantities of data, which can be used to drive efficiencies across virtually any business application including energy, logistics, occupant comfort, procurement, building management and performance and others. One of the core challenges in utilizing this data, however, is the need to make the data self-describing so that it is automatically understood and interpreted by those who depend on it to make intelligent business decisions. Many companies are adopting the Haystack Standard to reduce the cost of implementing solutions for their customers. Customers realize that by extending the range of applications offered to them that can easily interact with smart device data is a wise business practice.

Contemporary Controls exhibited our open standard, building automation networking solutions.

Niagara AX Integration via Haystack

The BASintegratorFIN uses a subset of J2innovations's FIN stack to create a powerful, yet flexible intelligent gateway that integrates Modbus and BACnet points up to Project Haystack clients.

The BASintegratorFIN uses a subset of J2innovations's FIN stack to create a powerful, yet flexible intelligent gateway that integrates Modbus and BACnet points up to Project Haystack clients.

Built on Contemporary Controls' open automation Linux platform, the BASintegratorFIN can discover points and apply Haystack tags to serve up to building supervisors such as Niagara's AX Supervisor. Using an open and free Haystack driver in the AX Supervisor, the AX Supervisor only needs to know the IP address of the BASintegratorFINs in the network for a seamless interface to all points on a job regardless of the type of point. The result is an inexpensive, yet modern approach to building automation where access to structured data is critical.

Project Haystack is an open-source initiative that incorporates a data model that creates structure to this data through naming conventions. The tagging convention is driven through public comment. Using Project Haystack conventions, the BASintegratorFIN not only provides structure to data but also captures the data in a cost-effective manner while delivering tagged field data up to building supervisors.

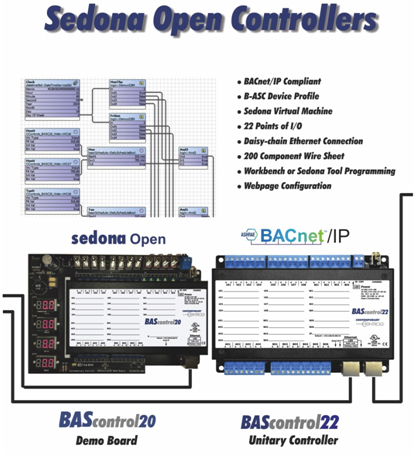

Sedona Open Controllers

May 2015- The BAScontrol22 Unitary Controller is a good example of an open controller in that it embodies the attributes of an open controller as defined by Contemporary Controls. It is BACnet/IP compliant and incorporates a Sedona Virtual Machine. It can be programmed using Niagara Workbench or with a Sedona Tool. It is available to any systems integrator without restriction.

May 2015- The BAScontrol22 Unitary Controller is a good example of an open controller in that it embodies the attributes of an open controller as defined by Contemporary Controls. It is BACnet/IP compliant and incorporates a Sedona Virtual Machine. It can be programmed using Niagara Workbench or with a Sedona Tool. It is available to any systems integrator without restriction.

By having an Ethernet connection, the BASC22 can easily connect to Niagara Workbench or a Sedona Tool for programming or to a web browser for configuration. A built-in 10/100 Mbps Ethernet switch allows for a daisy-chain connection to the next-in-line controller or to a building supervisor. Besides having 66 Sedona components from Tridium, it has 100 custom components from Contemporary Controls. These include 48 web components that can be viewed and manipulated by a web browser, and 24 virtual points that can be read or written by a BACnet client.

The BAScontrol20 Demo Board is ideal for training and simulation by having inputs and outputs pre-wired to physical points. Applications can be tested before being deployed in the field.

Automation Platform

Both the BASintegratorFIN and the BASsupervisorDG5 run on the powerful Automation Platform with a 1.2Ghz ARM9 processor, 512MB RAM and up to 8GB eMMC on-board flash memory. A built-in five-port Ethernet switch eliminates the need for a separate Ethernet switch in the panel. Two optically-isolated EIA-485 serial ports can connect to either BACnet MS/TP or Modbus RTU networks. BACnet/IP and Modbus TCP are supported via Ethernet ports. The unit supports IEEE 802.11b/g/n Wi-Fi and EnOcean wireless as an option. The compact unit operates from a 24 VAC/VDC supply and is DIN-rail mountable intended for standard control panels.

Both the BASintegratorFIN and the BASsupervisorDG5 run on the powerful Automation Platform with a 1.2Ghz ARM9 processor, 512MB RAM and up to 8GB eMMC on-board flash memory. A built-in five-port Ethernet switch eliminates the need for a separate Ethernet switch in the panel. Two optically-isolated EIA-485 serial ports can connect to either BACnet MS/TP or Modbus RTU networks. BACnet/IP and Modbus TCP are supported via Ethernet ports. The unit supports IEEE 802.11b/g/n Wi-Fi and EnOcean wireless as an option. The compact unit operates from a 24 VAC/VDC supply and is DIN-rail mountable intended for standard control panels.

The Automation Platform is intended as an OEM platform for the building and industrial automation industries. Its design is flexible in both hardware and software and powerful enough to serve in a supervisor, integrator or router application. Pre-loaded with a Linux OS, it can be modified by our technical staff to meet just about any requirement. Manufactured in either our U.S. or China plant, it will carry the necessary regulatory approvals for the industry being served.

View the Automation Platform Data Sheet to learn more.

Automation Platform-DG5 in a Box

A sophisticated graphical head-end can be found in the BASsupervisorDG5. Powered by DGLogik, the BASsupervisorDG5 has a HTML5 user interface with impressive graphics along with trending, alarming and scheduling. It is BACnet/IP compliant with two resident opto-isolated serial ports that can integrate to Modbus RTU as shown connected to a Cube I/O. Using a standalone BASrouter, a connection is made to a BACnet MS/TP Cube I/O.

A sophisticated graphical head-end can be found in the BASsupervisorDG5. Powered by DGLogik, the BASsupervisorDG5 has a HTML5 user interface with impressive graphics along with trending, alarming and scheduling. It is BACnet/IP compliant with two resident opto-isolated serial ports that can integrate to Modbus RTU as shown connected to a Cube I/O. Using a standalone BASrouter, a connection is made to a BACnet MS/TP Cube I/O.

A five-port Gigabit Ethernet switch facilitates IP connections. In addition to wired connections, the BASsupervisorDG5 has two wireless ports-Wi-Fi and EnOcean. The BASsupervisorDG5 is ideal where a comprehensive head-end is required along with wired and wireless connectivity options.

For small to medium-sized systems, the BASsupervisorDG5 can function as a stand-alone building controller. Flexibility is achieved through the two opto-isolated serial ports which can be individually configured for either Modbus RTU or BACnet MS/TP. Depending on serial port loading, it is possible to eliminate the BACnet router. With a built-in EnOcean Wi-Fi connectivity, flexibility extends beyond just a wired connection.