Success Story

ARCNET Server Links Dukane's Ultrasonic Plastic Welders to Ethernet Backbone

Since 1970, Dukane Corporation in St. Charles, Illinois, has been a global manufacturer and distributor of ultrasonic plastic welding systems. One of their current products, known as the Dynamic Process Controller™ (DPC), previously offered a graphic user interface via an MMI (Man-Machine Interface) using the ARCNET communication protocol. Software Engineering Manager Duke Syvongsa said due to obsolete components, the MMI product was no longer available. "We then offered our customers a browser-based interface (the iPC) running on the host PC and connecting with the plastic welding systems via serial and ARCNET ports. Since it exchanged the data with the welder via serial communication using 19.2k baud rate, the responses were slow and the through-put was low."

Subsequently, Dukane took one step further by providing their customers with a better and faster user interface program known as the DPC-GUI. Syvongsa said the DPC-GUI was developed after the DPC MMI product was discontinued and the iPC (Java application) product fell short of performance expectations. "The DPC-GUI can communicate to multiple DPC systems over a standard Ethernet network, while the iPC product communicated with only one dedicated DPC system using an RS-232 serial port connection," he explained.

The main function of the DPC-GUI is to allow the users to control and monitor the DPC systems. They can modify weld parameters and monitor the results of the process by reviewing either the raw data or the graphed data. The DPC systems include a variety of programmable parameters, which permit individuals to quickly weld plastic parts in a high-volume production environment. Syvongsa said this process can control the amount of ultrasonic energy (Watt-Seconds or Joules) applied to each part or can weld the plastic parts to a programmed dimension. "In addition," he said, "the process controller can be set for secondary measurement limits for better control and to determine if each joined plastic part, after completion, is good, bad or suspect, based on user-programmed measurement limits. Thus, these individuals can effectively manage this process in a very repeatable and reliable manner."

With the design of the DPC-GUI came the need for an ARCNET device that would enable Dukane engineers to switch from serial communication to Ethernet to increase through-put. Syvongsa indicated that Contemporary Controls was the only manufacturer that designed the AI-SRVR for converting ARCNET packets to Ethernet packets or vice versa. "We are using the AI-SRVR-1/TB5 models. The AI-SRVR enables the DPC-GUI application to network to DPC systems over a conventional Ethernet network instead of ARCNET. We have noticed that through-put is significantly faster than the serial communication. And for engineers/developers, with the AI-SRVR, they don't have to redesign the Ethernet communication card in order to improve through-put."

This product is the communication gateway used by the DPC-GUI and the welders to exchange the data/information. "For example, the user can setup parameters, monitor or view the welder with the data going to or coming from the AI-SRVR," said Syvongsa. "Currently, there's only one welder that's connected to it known as the LOCAL Welder. Those welders that are networking with the local welder are considered as REMOTE Welders. The AI-SRVR is connected between the ARCNET port on the DPC system and is a node on the Ethernet network. A dedicated AI-SRVR is needed for each DPC ARCNET network with which the DPC-GUI application will communicate."

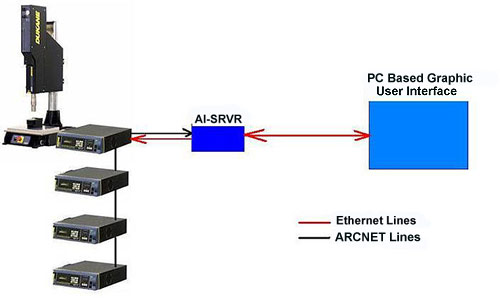

The diagram below illustrates how the AI-SRVR is being used for one of Dukane's existing products known as the DPC/4. The welders are setup in a networking mode. The top unit is considered a local unit while the others are considered remote units. A local unit communicates/exchanges data with the AI-SRVR in legacy ARCNET format and each remote unit also communicates, using ARCNET. From the AI-SRVR to the PC-based application, the data/information is in the form of Ethernet.

Syvongsa discussed the basic principle of ultrasonic plastic welding. He stated that the two thermoplastic parts to be assembled are placed together, one on top of the other, in a supportive nest called a fixture. "Now, an aluminum component called a horn is brought into contact with the upper plastic piece," he said. "A controlled pressure is applied to the parts, clamping them together against the fixture."

The horn is vibrated vertically 20,000 (20 KHz) or 40,000 (40 kHz) times per second, at distances measured in microns, for a predetermined amount of time called weld time. Syvongsa said mechanical vibrations are transmitted through the thermoplastic materials to the joint interface to create frictional heat. "When the temperature at the joint interface reaches the melting point, plastic melts and flows, and the vibrations stop, allowing the melted plastic to cool," he explained.

The clamping force is maintained for a specified amount of time allowing these pieces to fuse as the melted plastic cools and solidifies. This is known as hold time.

According to Syvongsa, once the melted plastic has solidified, the clamping force is removed and the horn is retracted. The two plastic parts are now joined and are removed from the fixture as one part. Since no solvents, adhesives or mechanical fasteners are required, finished assemblies are strong and clean.